This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Danish Port of Aarhus: new tug fitted with SCHOTTEL Rudderpropellers and mechanical hybrid solution

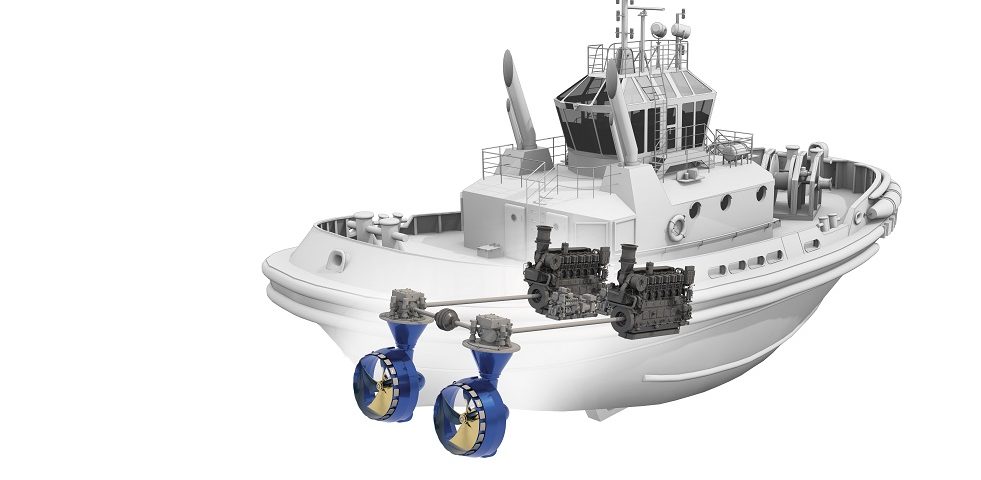

The German propulsion manufacturer SCHOTTEL has been awarded a contract to supply UZMAR Shipyard with rudder propellers featuring the patented hybrid system SYDRIVE-M. The Turkish shipyard is currently building a 30.25-metre long and 11.75-metre wide RAmparts 3000 series tugboat for the Port of Aarhus, Denmark’s largest container port.

The new tug features two SCHOTTEL Rudderpropellers type SRP 430 (2,000 kW each) with fixed pitch propellers measuring 2.5 metres in diameter. The azimuth thrusters will be driven by diesel engines. This configuration will achieve an expected bollard pull of about 65 tonnes and a free running speed of approximately 12.5 knots. As a mechanical hybrid solution without the costly complexity of common hybrid technology, SYDRIVE-M will ensure lower maintenance costs.

Better manoeuvrability, efficiency and precision

Thomas Haber Borch, Chief Executive Officer at the Port of Aarhus explains: “Not only does the tugboat have great strength, it also has significantly better manoeuvrability and thus efficiency and precision in the work it will undertake. It can assist the very large vessels arriving at Aarhus with pronounced precision, as it is delivered with an Azimuth Stern Drive system.

The yard lived up to all our minimum requirements, and at the same time they can deliver a tugboat that can sail on one engine as we sail back and forth to the ship to be towed, while we can use both of the ship’s engines during the actual towing,” he adds.

Less fuel consumption, lower emissions

SCHOTTEL SYDRIVE-M connects a port and starboard mounted azimuth thruster in a vessel, allowing the thrusters to be driven together by only one of the main engines. In turn, this leads to reduced operating hours of the main engines, resulting in lower maintenance costs as well as less fuel consumption and lower emissions.

Many advantages in main operation modes

The system needs no additional electronical components or a gearbox, which offers many advantages as demonstrated in these three main operation modes: Light Operation or Free Sailing Mode, Full Thrust Operation Mode and FiFi-Mode.

Greener operations, higher efficiency

The new tugboat, which is scheduled for delivery in summer 2021, will ensure greener operations and higher efficiency when it goes into operation at the Port of Aarhus. As Denmark’s largest commercial port, it has the country’s largest container terminal and the country’s largest public bulk turnover.