This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Kooiman Marine Group to design and build cutting-edge pusher tug for Verbund Hydro Power

Sanmar delivers two powerful new tugs to Turkiye’s Directorate General of Coastal Safety

25/01/2024

Med Marine successfully completed delivery of MED-A2575 RAmparts 2500-W series tugboat to Boluda Towage

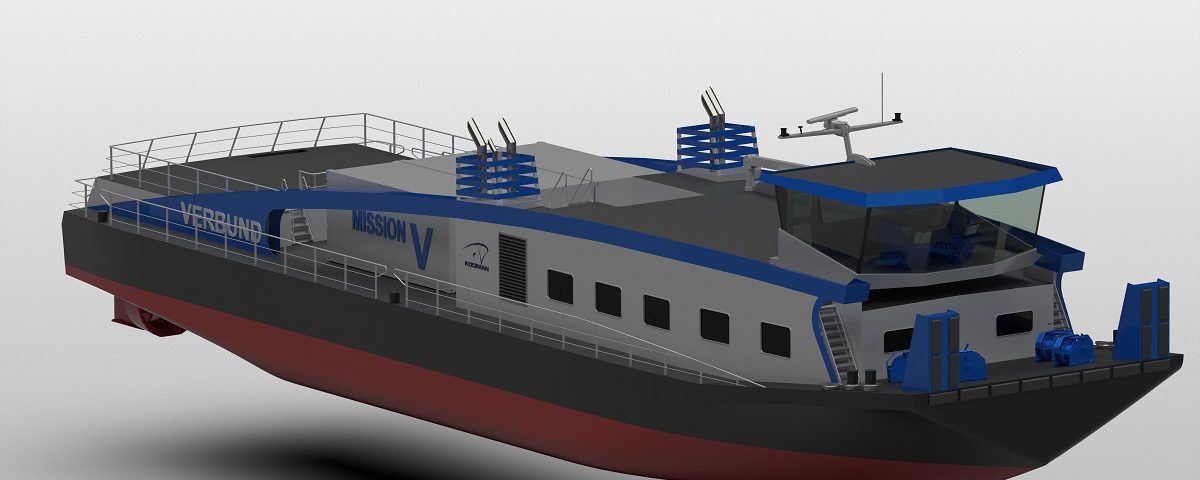

29/01/2024Kooiman Marine Group has recently received an order from VERBUND Hydro Power GmbH for a new vessel. The pusher tug will serve a dual purpose, facilitating the transport of split hopper barges and functioning as an icebreaker on the River Danube in Austria.

Prior to the securing the order, Kooiman Engineering, a division of the Kooiman Marine Group, developed a concept design in close collaboration with VERBUND Hydro Power GmbH. VERBUND is a leading electricity supplier in Austria and operates 10 hydropower plants on the River Danube. They require a pusher tug to handle a pair of split hopper barges which are used for the maintenance of the gravel bed around the dams. The vessel should be powerful enough to push the combination upstream.

Jiri de Vos, lead engineer at Kooiman, shared insights into the process: “At first, VERBUND did a market inquiry with a concept design. It became quickly obvious that the vessel would need to develop a very high pushing force in very shallow water. Due to our experience designing and building four powerful pusher tugs for Veerhaven and the very manoeuvrable workboats Zwerver 2 and 3, we were able to propose a suitable design.”

Beyond its primary role, the pusher tug will also be used to break ice, preventing the accumulation of drifting ice against the dams. As a producer of green energy, VERBUND is strongly engaged in the production and the application of hydrogen, as a means to reduce emissions of greenhouse gases and nitrogen oxides. The pusher tug will be prepared to enable an easy conversion to hydrogen for propulsion in the future. “It certainly won’t be an off-the-shelf ship”, smiles Jiri.

Christian Sagat, responsible for the fleet at VERBUND, praises the collaboration: “As we developed a vision for the new vessel, we conducted a survey of potential shipyards and identified Kooiman Marine Group as the ideal partner for our project. They had designed and built the successful Veerhaven pusher tugs. During our first conversations, we sensed the willingness of Kooiman to develop a vessel with us which would be fit to carry and integrate zero carbon energy sources which could be easily adapted in the future. We are very confident that they can deliver this vessel within the required delivery time and budget. We also really enjoy working with them!”

Jiri de Vos added, “There is quite a bit of ground to cover before we can go on sea trials. Kooiman Engineering will first detail the design. After that, we can do most of the work in-house, such as the ships interior, ships piping, machining of the propeller shafts and the outfitting at one of our three shipyards. We also bring a number of reliable suppliers onboard, so we can achieve an outstanding finished product.”

The Kooiman Marine Group houses all disciplines necessary for the design, build and delivery of new ships, compliant with the applicable regulations. With this order for the pusher tug for VERBUND, Kooiman demonstrates that bespoke solutions enable the efficient operation of pusher tugs with low emissions.

Main particulars of the vessel:

Length (over all): 40.00 m

Length (bpp): 40.00 m

Width (over all): 11.40 m

Depth: 3.40 m

Draft: 1.75 m

Accommodation: 5 persons